Hydrogen

We have verified the techno-economic feasibility of producing carbon-negative hydrogen (and CO2 for storage/usage) from non-recyclable waste. We are working on a project in South Norway and have more in the pipeline.

What is it?

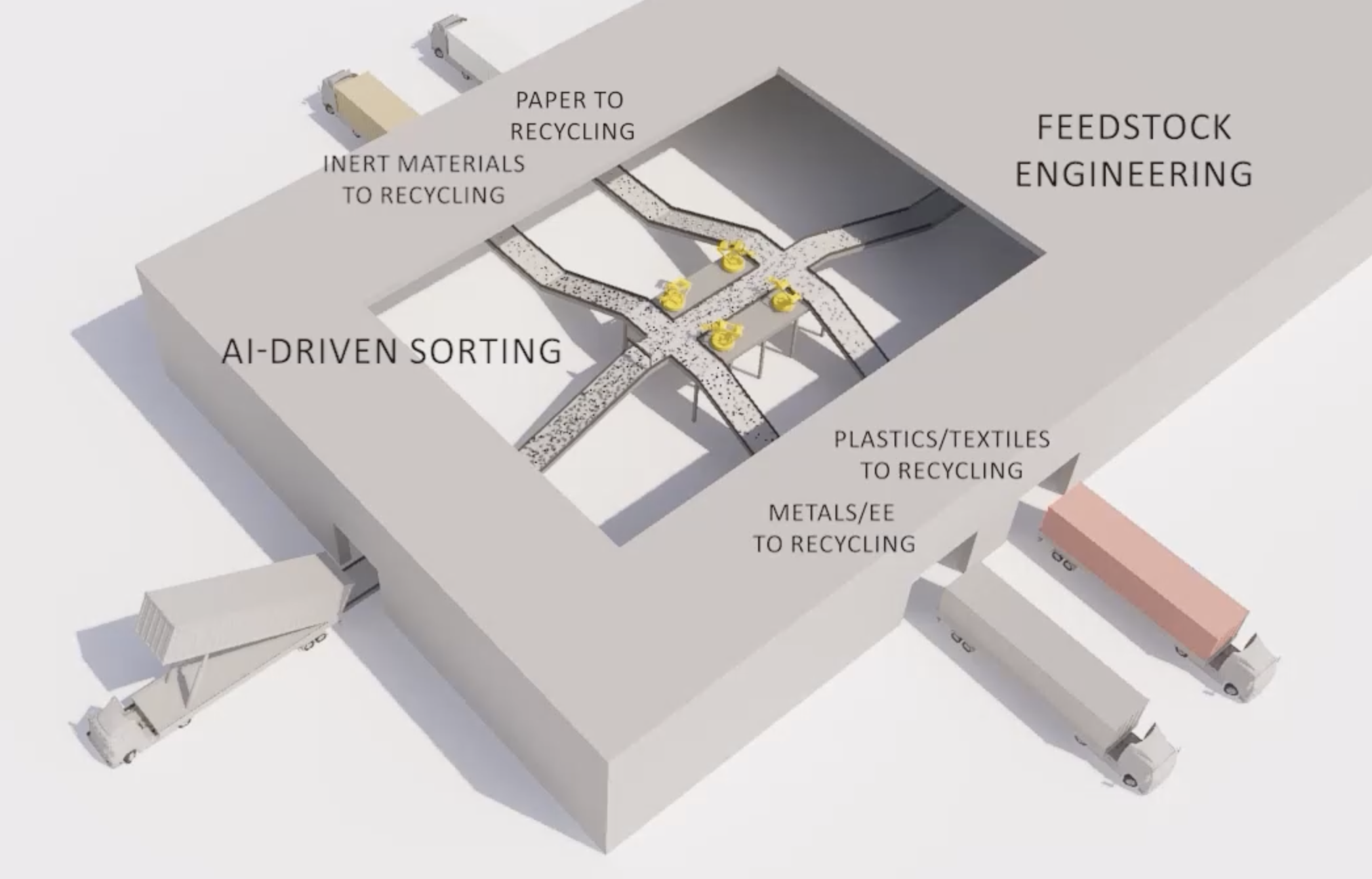

Hydrogen production from waste materials represents a transformative solution for addressing two critical challenges: waste management and clean energy generation. The solution both diverts waste from landfills and incineration and produces a valuable energy carrier. The first part of the process is gasification. The process treats waste materials at high temperatures (>1200°C) without combustion, breaking them down into a synthetic gas (syngas). The syngas is then cleaned and converted into hydrogen and CO₂, which can be captured.

Why?

Hydrogen’s role in a zero emission future is unequivocal. Global demand for hydrogen is expected to increase by more than 4x by 2050, and there is still a long way to go in decarbonizing the hydrogen that is used today. Producing hydrogen from waste is 5x more energy-efficient than electrolysis and has negative CO2 emissions due to the capture and storage of biogenic carbon. Hydrogen from waste contributes to a circular economy and reducing the reliance on fossil fuels.

Where can it be used?

Hydrogen can be used in a wide range of industrial processes, like steel and ammonia production, as a fuel in long-haul and maritime transportation, and as an energy storage solution for regulating intermittent energy production.

Want to know more?

Eva Aakre Vik

Project Director

Eva has 11 years of experience within the civil engineering industry, including Project Manager roles at Rambøll and Statkraft. At Statkraft, she worked on power-intensive industry early phase with a focus on hydrogen production. Eva holds an MSc in Environmental and Analytical Chemistry from NTNU, the Norwegian University of Science and Technology.